- Food & Beverage/Pharmaceutical

- Energy Saving System

- Wastewater Treatment System

- Water & Environment Plant

- Overview

- Evaporation/Crystallization System

- Distillation System

- Drying System

- Zero Liquid Discharge System

- Project Achievement

Evaporation System Using MVR

MVR is a system that recycles waste steam by mechanically compressing the steam evaporated from evaporator from external power and increasing the temperature of steam.

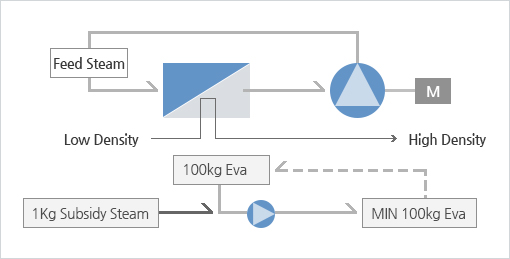

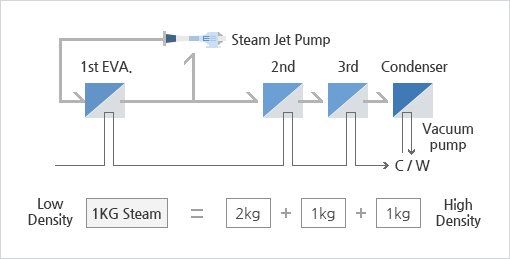

Evaporation System Using TVR

TVR is a system with reduction-expansion nozzles that recycles the waste steam by increasing the temperature and pressure of steam evaporated from the evaporator.

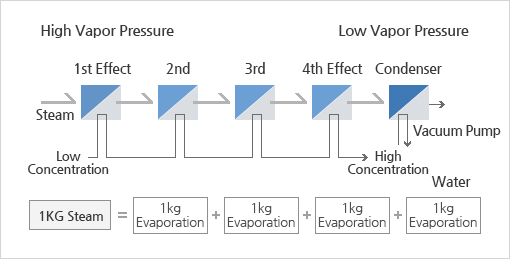

Multi-Effect EvaporationConcentration System

Multi-effect evaporation system uses the steam evaporated from the evaporator subsequently at the next evaporator as the heat source without using compressors such as MVR or TVR.

Crystallization System

Forced-circulation type crystallizer

Forced-circulation type crystallizer OSLO-type crystallizer 1

OSLO-type crystallizer 1 OSLO-type crystallizer 2

OSLO-type crystallizer 2

This system creates solid crystals from the process of increasing the concentration of liquid that can have energy saving effect as a result in combination with TVR or MVR.

Comparison of Steam Efficiency by Evaporation system type

Multiple-effect type

Multiple-effect type Multiple-effect type + TVR

Multiple-effect type + TVR Multiple-effect type + MVR

Multiple-effect type + MVR

| Multiple-effect type | Multiple-effect type+TVR | Multiple-effect type+MVR | |

|---|---|---|---|

| Theoretical steam efficiency | 5 kg / 1 kg = 5 | 6 kg / 1 kg = 6 | 100kg / 1kg = 100 |

| Actual steam efficiency | 4.3 ~ 4.4 | 6.1 ~ 6.2 | 85.7 |

| TYPE | 5-Effect Evaporator |

5-Effect Evaporator With TVR |

2 Serial Evaporator With MVR |

| CUSTOMER | A | A | C |

| CAPA | 60T/h Water 13.9T/h Steam |

60T/h Water 9.7T/h Steam |

60T/h Water 0.7/h Steam |