의료법인 유투의료재단 신축공사

-

Location

열분해

-

Client

의료법인 유투의료재단

-

용도

1종 근린생활시설1종

-

규모

지하3층~지상7층 / 7,917.81㎡

-

공사기간

2025.02 ~ 2026.12

Scroll Down

We deliver high-efficiency turnkey plants across multiple industries, backed by innovative concentration and crystallization technology.

Integrated Production

& Wastewater Treatment Plants

Integrated Production

& Wastewater Treatment Plants

Proven Expertise in Food

Bio & Secondary Battery Sectors

Proven Expertise in Food

Bio & Secondary Battery Sectors

Energy-Saving

Technology

Energy-Saving

Technology

Reduced operating costs and carbon emissions.

Extensive Project

Experience

Extensive Project

Experience

Integrated Plant Solutions Covering Production and Wastewater Treatment

Types of Evaporator

Swipe left or right to view the content.

Swipe left or right to view the content.| Type |

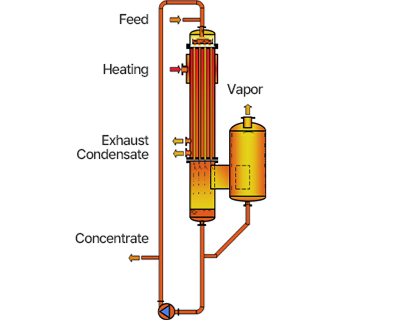

Falling Film Evaporator

|

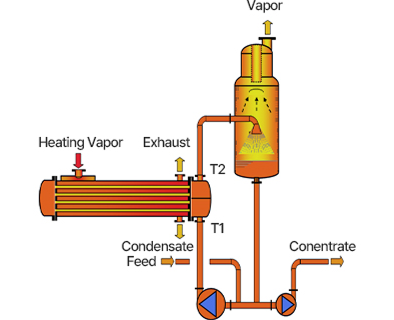

Forced Circulation Evaporator

|

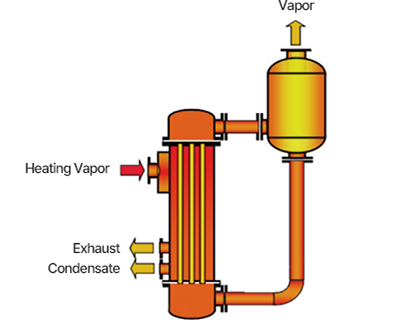

Natural Circulation Evaporator

|

|---|---|---|---|

| Applicable Fluids |

|

|

|

| Advantages & Disadvantages |

|

|

|

| Typical Applications |

|

|

|

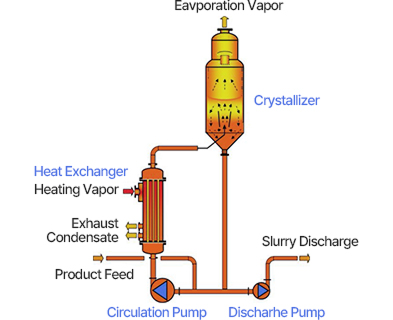

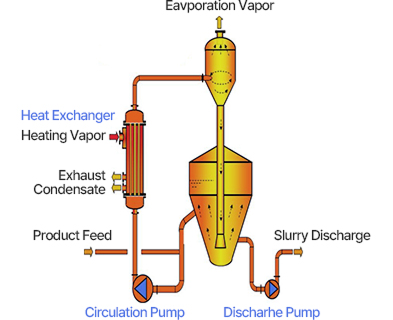

Types of Crystallizers

Swipe left or right to view the content.

Swipe left or right to view the content.| Type |

Forced Circulation Vortex Crystallizer

|

Forced Circulation D.T.B. Crystallizer

|

Oslo Crystallizer

|

|---|---|---|---|

| Applicable Fluids |

|

|

|

| Advantages & Disadvantages |

|

|

|

| Typical Applications |

|

|

|

Dryers

Swipe left or right to view the content.

Swipe left or right to view the content.| Fluidized Bed Dryer (FBD) | Spray Dryer (SD) | |

|---|---|---|

| Heating Temperature | 50°C ~ 100°C (low-temperature drying) | 150°C ~ 300°C (high-temperature rapid drying) |

| Heat Energy Consumption | Moderate heat energy consumption Efficient energy distribution |

High energy consumption due to fast drying |

| Exhaust Air Volume | Relatively low air consumption | High air consumption and large exhaust gas treatment facilities required |

| Cost | Relatively low installation and maintenance costs | High installation and maintenance costs |

| Installation Space | Compact and space-efficient design | Relatively large installation space needed |

| Energy Efficiency | Good energy efficiency Uniform drying rate |

Low energy efficiency due to high drying temperature and air volume |

| Application Industries |

|

|

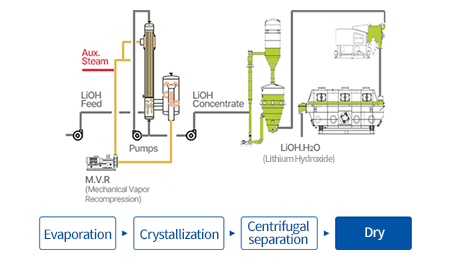

MVR (Mechanical Vapor Recompression)

Compresses and heats vapor from the evaporator using external power, allowing efficient reuse and significant energy savings.

TVR (Thermal Vapor Recompression)

Uses a converging-diverging nozzle to boost vapor temperature and pressure for efficient reuse.

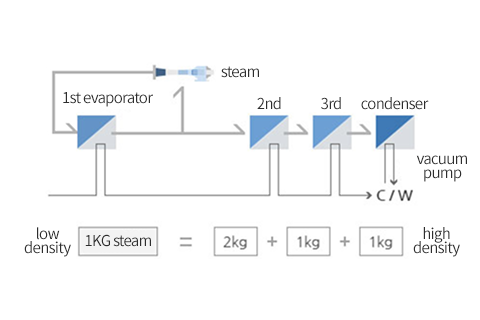

Multiple Effect Evaporation (MEE)

A system that sequentially uses vapor generated from one evaporator as the heat source for the next, without relying on compression devices like MVR or TVR.

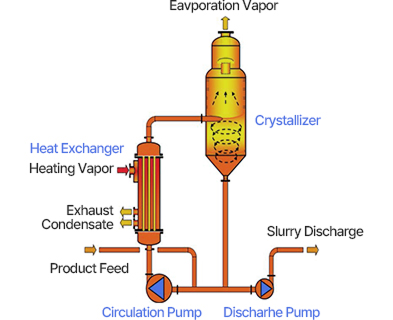

Crystallization Systems

A system that forms solid crystals by concentrating a liquid solution.

It can be integrated with TVR and MVR technologies to achieve energy savings.

Comparison of Steam Efficiency by Type of Evaporator

| Evaporator |

Multi-Effect Type

|

Multi-Effect + TVR Type

|

Multi-Effect + MVR

|

|---|---|---|---|

| Theoretical Steam Efficiency | 5 kg / 1 kg = 5 | 6 kg / 1 kg = 6 | 100kg / 1kg = 100 |

| Actual Steam Efficiency | 4.3 ~ 4.4 | 6.1 ~ 6.2 | 85.7 |

| TYPE |

5-Effect Evaporator |

5-Effect Evaporator With TVR |

2 Serial Evaporator With MVR |

| CUSTOMER | A | A | C |

| CAPA |

60T/h Water 13.9T/h Steam |

60T/h Water 9.7T/h Steam |

60T/h Water 0.7/h Steam |

Secondary Battery Material Equipment

Lithium Hydroxide & Lithium Carbonate

Lithium hydroxide and lithium carbonate are primarily used for high-capacity electric vehicle batteries due to their ease of synthesis with nickel, which enhances battery capacity. Additionally, they possess strong electrochemical properties and are commonly utilized as lithium oxide forms in battery cathode materials. Welcron Hantec provides a turnkey process that evaporates and crystallizes supplied lithium hydroxide and lithium carbonate aqueous solutions into saturated solutions, followed by dehydration and drying.

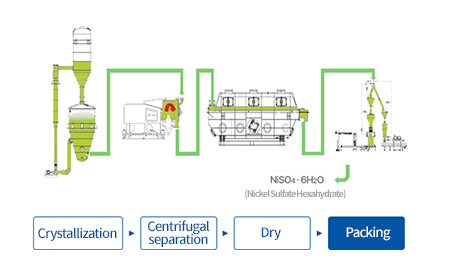

Nickel Sulfate, Cobalt Sulfate, Manganese Sulfate

Nickel sulfate, cobalt sulfate, and manganese sulfate are raw materials used to produce cathode materials, which are essential components of secondary batteries. Welcron Hantec offers a turnkey process that includes evaporates and crystallizing supplied aqueous solutions of nickel sulfate, cobalt sulfate, and manganese sulfate, followed by dehydration, drying, and packaging.

Solvent Recovery System

The separator is a critical component in all secondary batteries, as it separates the anode and cathode while enabling fast ion transport through the electrolyte,

which is essential for battery performance and safety.

Welcron Hantec’s solvent recovery system plays a vital role in the wet process of separator manufacturing. It recovers high-purity, high-value methylene chloride (MC) from wastewater mixed with oil and used MC, allowing for its reuse. This advanced solution contributes significantly to reducing production costs and improving process efficiency.

| Machine Specification | |

|---|---|

| Waste MC처리량 | 10m3/hr ~ 45m3/hr |

| MC Recovery Ratio | 99% or more |

| DistillatedMC Condition |

|

| Refined Oil Condition |

|

Crystallizer Installation (C1, C2 Lines)

MC Distillation & LP Refinery System

MC & Oil Refinery System

Lysine Concentration Facility

High Concentration Recovery MVR Facility

Ammonium Sulfate & Process Wastewater Concentration & Crystallization Facility

Swipe left or right to view the content.

Swipe left or right to view the content.| Project Name | Industry | Site | Specification | Completion Year | Remarks |

|---|---|---|---|---|---|

| Sodium Sulfate & By-product Crystallization Facility | Secondary Battery | Korea | MVR Evaporator & Crystallizer, Capacity: 153,100 kg/hr | 2024 | - |

| Liquid Sugar Concentration Facility | Cornstarch | Overseas | 4-Effect Evaporator + TVR, Capacity: 35,000 kg/hr | 2024 | - |

| Nickel Sulfate, Cobalt Sulfate, Manganese Sulfate Crystallization, Separation & Drying Facility | Secondary Battery | Korea | MVR Evaporator & Crystallizer, Capacity: Ni 38,202 / Co 4,922 / Mn 4,566 kg/hr | 2024 | - |

| Cobalt Sulfate & Nickel Sulfate Crystallization Facility | Secondary Battery | Korea | MVR Evaporator & Crystallizer, Capacity: Ni 26,843 / Co 4,934 kg/hr | 2024 | - |

| Li Solution 1-Stage MVR Concentration Facility | Secondary Battery | Korea | MVR Evaporator & Crystallizer, Capacity: Ni 26,843 / Co 4,934 kg/hr | 2023 | - |

| Sodium Sulfate & By-product Crystallization Facility | Secondary Battery | Korea | MVR Evaporator & Crystallizer, Capacity: 62,500 kg/hr | 2022 | - |

| Sodium Sulfate & By-product Crystallization Facility | Secondary Battery | Korea | MVR Evaporator & Crystallizer, Capacity: 11,620 kg/hr | 2022 | - |

| Allulose Concentration Facility | Cornstarch | Korea | 3-Effect Evaporator & Finisher + TVR, Capacity: 12,730 kg/hr | 2022 | - |

| Nickel Sulfate / Cobalt Sulfate / Manganese Sulfate Crystallization Facility | Secondary Battery | Korea | MVR Evaporator & Crystallizer, Capacity: Ni 23,109 / Co 3,587 / Mn 3,662 kg/hr | 2022 | - |

| Cathode Material Wastewater Concentration & Crystallization Facility | Secondary Battery | Korea | MVR Evaporator & Crystallizer, Capacity: 27,000 kg/hr | 2022 | - |

| Lithium Sulfate, Lithium Hydroxide, Lithium Carbonate Crystallization Facility | Secondary Battery | Korea | MVR Evaporator & Crystallizer, Capacity: 1,875 / 4,100 / 14,000 kg/hr | 2022 | - |

| Valine & Isoleucine Crystallization Facility | Bio | Overseas | Crystallizer + TVR, Capacity: 21.7 m³/hr / 16.4 m³/hr | 2022 | - |

| Nickel, Cobalt & Manganese Sulfate Crystallization Facility | Secondary Battery | Korea | MVR Evaporator & Crystallizer, Capacity: Ni 18,000 / Co 2,987 / Mn 2,470 kg/hr | 2021 | - |

| Nickel Sulfate, Cobalt Sulfate, Manganese Sulfate & Sodium Sulfate Concentration & Crystallization Facility | Secondary Battery | Korea | MVR Evaporator & Crystallizer, Capacity: Ni 3,600 / Co 1,000 / Mn 12,000 / Na₂SO₄ 41,145 kg/hr | 2021 | - |

| Threonine Concentration Facility | Bio | Overseas | 2-Effect F/C Evaporator, Capacity: 8,600 kg/hr | 2021 | - |

| Li Solution 1-Stage MVR Concentration Facility | Secondary Battery | Korea | F/F Evaporator + MVR, Capacity: 12,500 kg/hr | 2021 | - |

| Tryptophan Evaporation & Crystallization Facility | Bio | Overseas | 4-Effect Evaporator & Crystallizer + TVR, Capacity: 14,800 / 9,232 kg/hr | 2017 | - |

| Crystallizer Installation (C1, C2 Lines) | Bio | Overseas |

C1: 3-Effect Evaporator & Crystallizer x2, 56,210 kg/hr each C2: 3-Effect Evaporator & Crystallizer x2, 52,050 kg/hr each |

2017 | - |

| MC Distillation & LP Refinery System | Secondary Battery | Korea | Distillator, Capacity: 13,136 kg/hr | 2017 | - |

| MC Distillation & LP Refinery System | Secondary Battery | Overseas | Distillator, Capacity: 18,390 kg/hr | 2016 | - |

| MC Distillation & LP Refinery System | Secondary Battery | Overseas | Distillator, Capacity: 15,630 kg/hr | 2016 | - |

| Tryptophan Evaporation & Crystallization Facility | Bio | Overseas | 5-Effect Evaporator + TVR, Capacity: 45,675 kg/hr | 2016 | - |

| Methionine Evaporation & Crystallization Facility | Bio | Overseas | 3-Effect Evaporator, Capacity: 34,700 kg/hr | 2015 | - |

| Liquid Sugar Concentration Facility | Cornstarch | Korea | 4-Effect Evaporator + TVR, Capacity: 22,000 kg/hr | 2015 | - |

| Infant Formula Concentrator Installation | Dairy | Korea | Evaporator + MVR x2, Capacity: 18,000 kg/hr | 2014 | - |

| Methionine Evaporation & Crystallization Facility | Bio | Overseas |

3-Effect Evaporator & Crystallizer, Capacity: 61,000 kg/hr x4 6-Effect Evaporator, 93,318 kg/hr 2-Effect Crystallizer, 21,650 kg/hr x2 3-Effect Evaporator, 10,910 kg/hr 3-Effect Crystallizer, 28,800 kg/hr |

2014 | - |

| Food & Livestock Wastewater Treatment Facility | Municipality | Korea | Evaporator + MVR & 2-Effect + TVR, Capacity: 20,000 kg/hr | 2014 | - |

| Lysine Concentration & Crystallization Facility | Bio | Overseas | Multiple Evaporators & Crystallizers, Capacity: up to 144,200 kg/hr | 2012 | - |

| Concentration & Crystallization Facility | Bio | Overseas | 4-Effect Evaporator & Crystallizer, Capacity: 18,600 kg/hr | 2012 | - |

| MC & Oil Refinery System | Secondary Battery | Korea | Distillator, Capacity: 11,000 kg/hr | 2011 | - |

| Lysine Concentration & Crystallization Facility | Bio | Overseas | Evaporators & Crystallizers, Capacity: 5,500 ~ 144,200 kg/hr | 2011 | - |

| Starch Syrup Concentration Facility | Cornstarch | Korea | 4-Effect Evaporator + TVR, Capacity: 11,500 kg/hr | 2010 | - |

| MC & Oil Refinery System | Secondary Battery | Korea | Distillator, Capacity: 6,630 kg/hr | 2010 | - |

| Lysine Concentration Facility | Bio | Overseas | 5-Effect Evaporator + TVR, Capacity: 41,200 kg/hr | 2009 | - |

| High Concentration Recovery MVR Facility | Bio | Korea | 2-Effect Evaporator + MVR, Capacity: 105,890 kg/hr | 2009 | - |

| Ammonium Sulfate & Process Wastewater Concentration & Crystallization Facility | Bio | Overseas | Evaporator + MVR, Capacity: 75,000 kg/hr / 10,500 kg/hr | 2009 | - |

| Sugar MVR Concentration Facility | Sugar | Korea | 2-Effect Evaporator + MVR | 2007 | - |

| Lysine & Ammonium Sulfate Concentration & Crystallization Facility | Bio | Overseas | Evaporators & Crystallizers, Capacity: 6,400 ~ 30,700 kg/hr | 2006 | - |

| Lysine & Ammonium Sulfate Concentration & Crystallization Facility | Bio | Overseas | Evaporators & Crystallizers, Capacity: 3,640 ~ 49,383 kg/hr | 2006 | - |

| Glucose Syrup MVR Concentration Facility | Cornstarch | Korea | Evaporator + MVR, Capacity: 33,170 kg/hr | 2005 | - |

| Ammonium Sulfate Crystallization Facility | Bio | Overseas | 3-Effect Evaporator & Crystallizer, Capacity: 48,000 kg/hr | 2003 | - |

| CSL MVR Concentration Facility | Cornstarch | Korea | Evaporator + MVR, Capacity: 28,774 kg/hr | 2001 | - |